WQB Plant submersible sewage pump

Product overview

WQB series flameproof submersible sewage electric pump for factory use is a new type of explosion-proof product developed by our company. The explosion-proof performance is in accordance with GB3836.1-2010 "Explosive Environment Part 1: General Requirements for equipment" and GB3836.2-2010 "Explosive environment Part 2: Equipment protected by flameproof enclosure "d" standard requirements made of flameproof type, explosion-proof mark: ExdIIBT4. The whole series of products are explosion-proof certificate, complete models, easy selection.

The main purpose

The product is used for sewage discharge in the factory where combustible gas or explosive mixture formed by steam and air is of grade ⅡB, temperature group T1-T4. Suitable for coal chemical industry, petrochemical industry, municipal engineering, urban industry, hospitals, hotels, residential areas and other places.

Conditions of use

1. In accordance with the product explosion-proof mark with flameproof requirements.

2. Power supply voltage: 380V, 660V, 1140V, three-phase, 50Hz.

3. Transmission medium temperature: 0-40℃ (more than this temperature and hot water pump).

4 delivery medium PH value: 5-9.

5. Medium weight: ≤1100Kg/m3.

6. Maximum diving depth: 10m.

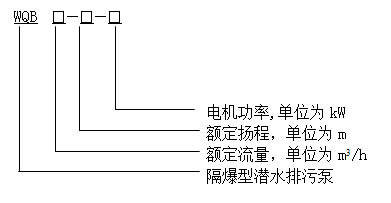

Model significance

Explosion-proof points

When the explosive gas mixture inside the flameproof submersible pump motor explodes, the flameproof enclosure shall not be damaged, and the internal flame will not ignite the explosive environment formed by one or more gases or vapors outside through the flameproof enclosure joint surface. The parts that make up the flameproof enclosure are hydrostatic tested in accordance with GB3836.2-2000 to ensure that they can withstand the maximum internal explosion pressure.

The flameproof mark of this flameproof submersible sewage pump is ExdIIBT4, which is suitable for the explosive mixture of combustible gas or steam and air formed by the temperature group T1-T4 in the factory class ⅡB. The maximum surface temperature of the unit must conform to the following table:

温度组别 | T1 | T2 | T3 | T4 |

允许最高表面温度 | 450 | 300 | 200 | 135 |

性能参数表

序号 | 型 号 | 流量 | 扬程 | 同步转速 | 功率 | 效率 | 排出口径 |

1 | 10-15-1.5 | 10 | 15 | 3000 | 1.5 | 31 | 50 |

2 | 15-16-1.5 | 15 | 16 | 32.5 | |||

3 | 25-7-1.5 | 25 | 7 | 35.5 | |||

4 | 15-22-2.2 | 15 | 22 | 2.2 | 36 | ||

5 | 25-10-2.2 | 25 | 10 | 36 | |||

6 | 35-7-2.2 | 35 | 7 | 38 | |||

7 | 10-32-3 | 10 | 32 | 3 | 31 | ||

8 | 15-25-3 | 15 | 25 | 31.5 | |||

9 | 25-15-3 | 25 | 15 | 37 | |||

10 | 40-12-3 | 40 | 12 | 41.5 | 65 | ||

11 | 52-7-3 | 52 | 7 | 41.5 | 80 | ||

12 | 15-32-4 | 15 | 32 | 4 | 34.6 | 50 | |

13 | 20-30-4 | 20 | 30 | 41 | |||

14 | 25-22-4 | 25 | 22 | 37.8 | |||

15 | 50-15-4 | 50 | 15 | 43.3 | 80 | ||

16 | 75-8-4 | 75 | 8 | 44 | 100 | ||

17 | 12-50-5.5 | 12 | 50 | 5.5 | 33 | 50 | |

18 | 20-40-5.5 | 20 | 40 | 34 | |||

19 | 30-30-5.5 | 30 | 30 | 44 | |||

20 | 40-20-5.5 | 40 | 20 | 44.5 | |||

21 | 70-15-5.5 | 70 | 15 | 45.8 | 80 | ||

22 | 100-10-5.5 | 100 | 10 | 52.5 | 100 | ||

23 | 25-50-7.5 | 25 | 50 | 7.5 | 46.7 | 50 | |

24 | 30-36-7.5 | 30 | 36 | 44.5 | |||

25 | 50-30-7.5 | 50 | 30 | 55 | |||

26 | 75-20-7.5 | 75 | 20 | 55 | 80 | ||

27 | 100-15-7.5 | 100 | 15 | 55.3 | 100 | ||

28 | 145-10-7.5 | 145 | 10 | 3000 | 7.5 | 56.5 | 150 |

29 | 20-65-11 | 20 | 65 | 1500 | 11 | 38.6 | 50 |

30 | 40-40-11 | 40 | 40 | 46 | 80 | ||

31 | 50-35-11 | 50 | 35 | 56 | |||

32 | 80-20-11 | 80 | 20 | 56.5 | 100 | ||

33 | 150-15-11 | 150 | 15 | 55.8 | 150 | ||

34 | 200-10-11 | 200 | 10 | 57.5 | |||

35 | 40-50-15 | 40 | 50 | 15 | 44 | 80 | |

36 | 60-35-15 | 60 | 35 | 45.3 | 100 | ||

37 | 100-22-15 | 100 | 22 | 48.6 | |||

38 | 170-18-15 | 170 | 18 | 56.5 | 150 | ||

39 | 200-15-15 | 200 | 15 | 57 | |||

40 | 300-10-15 | 300 | 10 | 58 | 200 | ||

41 | 80-35-18.5 | 80 | 35 | 18.5 | 47 | 100 | |

42 | 100-30-18.5 | 100 | 30 | 48 | |||

43 | 150-25-18.5 | 150 | 25 | 57.5 | 150 | ||

44 | 250-15-18.5 | 250 | 15 | 59 | 200 | ||

45 | 40-80-22 | 40 | 80 | 22 | 44 | 80 | |

46 | 60-50-22 | 60 | 50 | 45.8 | |||

47 | 80-40-22 | 80 | 40 | 47 | |||

48 | 150-30-22 | 150 | 30 | 59.3 | 150 | ||

49 | 200-20-22 | 200 | 20 | 60 | |||

50 | 300-15-22 | 300 | 15 | 61 | 200 | ||

51 | 80-60-30 | 80 | 60 | 30 | 48.5 | 80 | |

52 | 120-50-30 | 120 | 50 | 57.8 | 150 | ||

53 | 200-30-30 | 200 | 30 | 59 | |||

54 | 300-20-30 | 300 | 20 | 61 | 200 | ||

55 | 400-15-30 | 400 | 15 | 1500 | 30 | 63 | 200 |

56 | 100-70-37 | 100 | 70 | 37 | 58.5 | 100 | |

57 | 150-45-37 | 150 | 45 | 62 | 150 | ||

58 | 350-25-37 | 350 | 25 | 69.5 | 200 | ||

59 | 500-15-37 | 500 | 15 | 72 | 250 | ||

60 | 150-50-45 | 150 | 50 | 45 | 57 | 150 | |

61 | 400-25-45 | 400 | 25 | 66 | 200 | ||

62 | 500-20-45 | 500 | 20 | 67 | 250 | ||

63 | 600-15-45 | 600 | 15 | 69 | |||

64 | 150-70-55 | 150 | 70 | 55 | 58 | 150 | |

65 | 200-50-55 | 200 | 50 | 59 | |||

66 | 400-30-55 | 400 | 30 | 66.6 | 200 | ||

67 | 500-25-55 | 500 | 25 | 68.3 | 250 | ||

68 | 600-20-55 | 600 | 20 | 68.5 | |||

69 | 200-70-75 | 200 | 70 | 75 | 58 | 150 | |

70 | 300-50-75 | 300 | 50 | 60.5 | 200 | ||

71 | 400-40-75 | 400 | 40 | 67 | |||

72 | 600-28-75 | 600 | 25 | 68 | 250 | ||

73 | 800-20-75 | 800 | 20 | 69 | 300 | ||

74 | 220-70-90 | 220 | 70 | 90 | 58.5 | 150 | |

75 | 300-60-90 | 300 | 60 | 62 | 200 | ||

76 | 500-35-90 | 500 | 35 | 64 | |||

77 | 900-20-90 | 900 | 20 | 70 | 300 | ||

78 | 400-60-110 | 400 | 60 | 110 | 69.8 | 200 | |

79 | 600-40-110 | 600 | 40 | 70 | 250 | ||

80 | 700-32-110 | 700 | 32 | 71.5 | |||

81 | 1000-25-110 | 1000 | 25 | 73 | 300 | ||

82 | 600-50-132 | 600 | 50 | 1500 | 132 | 70 | 200 |

83 | 500-60-132 | 500 | 60 | 69 | |||

84 | 800-35-132 | 800 | 35 | 69.8 | 250 | ||

85 | 1000-30-132 | 1000 | 30 | 80 | 300 | ||

86 | 700-50-160 | 700 | 50 | 160 | 71.3 | 250 | |

87 | 1000-35-160 | 1000 | 35 | 75 | 350 | ||

88 | 1500-25-160 | 1500 | 25 | 76.5 | 400 | ||

89 | 2000-20-160 | 2000 | 20 | 80 | |||

90 | 800-50-185 | 800 | 50 | 185 | 72.3 | 250 | |

91 | 1000-40-185 | 1000 | 40 | 73.8 | 300 | ||

92 | 1500-30-185 | 1500 | 30 | 74.9 | 400 | ||

93 | 2500-18-185 | 2500 | 18 | 81.4 | 500 | ||

94 | 1200-40-200 | 1200 | 40 | 200 | 76 | 350 | |

95 | 1500-32-200 | 1500 | 32 | 77.4 | 400 | ||

96 | 2000-25-200 | 2000 | 25 | 80 | |||

97 | 3000-16-200 | 3000 | 16 | 79.8 | 500 |